The humble lorry, a workhorse of global commerce, silently and efficiently transports goods across continents. But behind its seemingly monolithic facade lies a complex structure comprised of numerous components working in perfect harmony. Understanding the "Parts Of A Lorry Body By Name" is crucial for anyone involved in logistics, transport, maintenance, or even just appreciating the engineering marvel that keeps our world moving. This article provides a comprehensive guide, breaking down the lorry body into its constituent parts, explaining their functions, and offering practical insights for those looking to deepen their knowledge.

Why Understanding Lorry Body Parts Matters

Decoding the Metal Beast: A Comprehensive Guide to Lorry Body Parts by Name

Knowing the names and functions of lorry body parts isn't just for mechanics. It empowers:

- Effective Communication: Accurately describing a damaged part when reporting an accident or requesting repairs.

- Informed Decision-Making: Evaluating the quality and suitability of a lorry body for specific transport needs.

- Cost-Effective Maintenance: Identifying potential problems early and preventing costly breakdowns.

- Safety: Understanding how different components contribute to the overall safety and stability of the vehicle.

I. The Foundation: Chassis and Subframe

The foundation of any lorry body is the chassis. While technically not part of the body itself, it's the structural framework upon which everything else is built. The chassis is typically constructed from high-strength steel and provides the rigidity and load-bearing capacity necessary for heavy-duty transport.

- Chassis Rails: These are the main longitudinal beams that run the length of the chassis. They are the primary load-bearing components.

- Cross Members: These transverse beams connect the chassis rails, providing lateral stability and preventing twisting.

On top of the chassis sits the subframe. The subframe acts as an intermediary structure between the chassis and the actual body of the lorry. It helps to distribute the load evenly, reducing stress on the chassis and allowing for a more robust body construction.

- Subframe Rails: Similar to chassis rails, but specifically designed to support the body.

- Outriggers: Protruding supports that extend outwards from the subframe, providing a wider base for mounting the body panels.

II. Enclosing the Cargo: Body Panels and Structure

The body panels are what most people readily recognize as the lorry body. They enclose the cargo area and provide protection from the elements. The type of panels and their construction vary depending on the lorry's intended use.

- Side Panels: These form the sides of the lorry body. They can be made from steel, aluminum, fiberglass, or composite materials.

- Front Bulkhead: The panel at the front of the body, separating the cargo area from the cab. It provides crucial structural support and protection for the driver in case of load shift.

- Rear Doors/Tailgate: These provide access to the cargo area from the rear. Common types include:

- Barn Doors: Two hinged doors that swing outwards.

- Roller Shutter Doors: A door that rolls up into a housing above the opening.

- Tailgate: A hinged panel that folds down, providing a loading platform.

- Roof: Covers the cargo area from above, protecting it from rain, snow, and sun.

- Floor: The base of the cargo area, typically made from wood, steel, or composite materials.

The structural elements that support these panels are equally important:

- Vertical Posts/Stanchions: Upright supports that reinforce the side panels and roof.

- Horizontal Rails/Longitudinals: Running along the sides and roof, these rails provide additional structural integrity.

- Corner Pillars: Located at the corners of the body, these pillars reinforce the joints and provide strength.

III. Securing the Load: Restraints and Tie-Downs

Keeping the cargo secure is paramount for safety and preventing damage. Lorry bodies are equipped with various restraint systems:

- Tie-Down Points/Lashing Rings: Anchors fixed to the floor or side panels, allowing straps and chains to secure the load.

- Load Restraint Bars/Shoring Beams: Adjustable bars that can be placed across the width of the body to prevent cargo from shifting.

- Cargo Nets: Large nets that can be used to cover and secure loose items.

- Internal Strapping Systems: Integrated straps that run along the interior of the body, allowing for quick and easy load securing.

IV. Specialized Features: Tail Lifts, Curtainsiders, and Refrigeration Units

Many lorries are equipped with specialized features to enhance their functionality:

- Tail Lift: A platform that can be raised and lowered to facilitate loading and unloading of heavy items. Key components include:

- Platform: The lifting surface.

- Hydraulic Cylinders: Power the lifting mechanism.

- Control Panel: Allows the operator to control the lift.

- Curtainsider/Tautliner: A type of lorry body with flexible side curtains that can be easily opened for side loading.

- Curtains: The flexible side panels.

- Ratchet Straps: Used to tension the curtains and secure the load.

- Tracks: Guide the curtains along the sides of the body.

- Refrigeration Unit: A system for maintaining a specific temperature inside the cargo area, used for transporting perishable goods.

- Compressor: Compresses the refrigerant.

- Condenser: Dissipates heat from the refrigerant.

- Evaporator: Absorbs heat from the cargo area.

- Temperature Controller: Allows the operator to set and maintain the desired temperature.

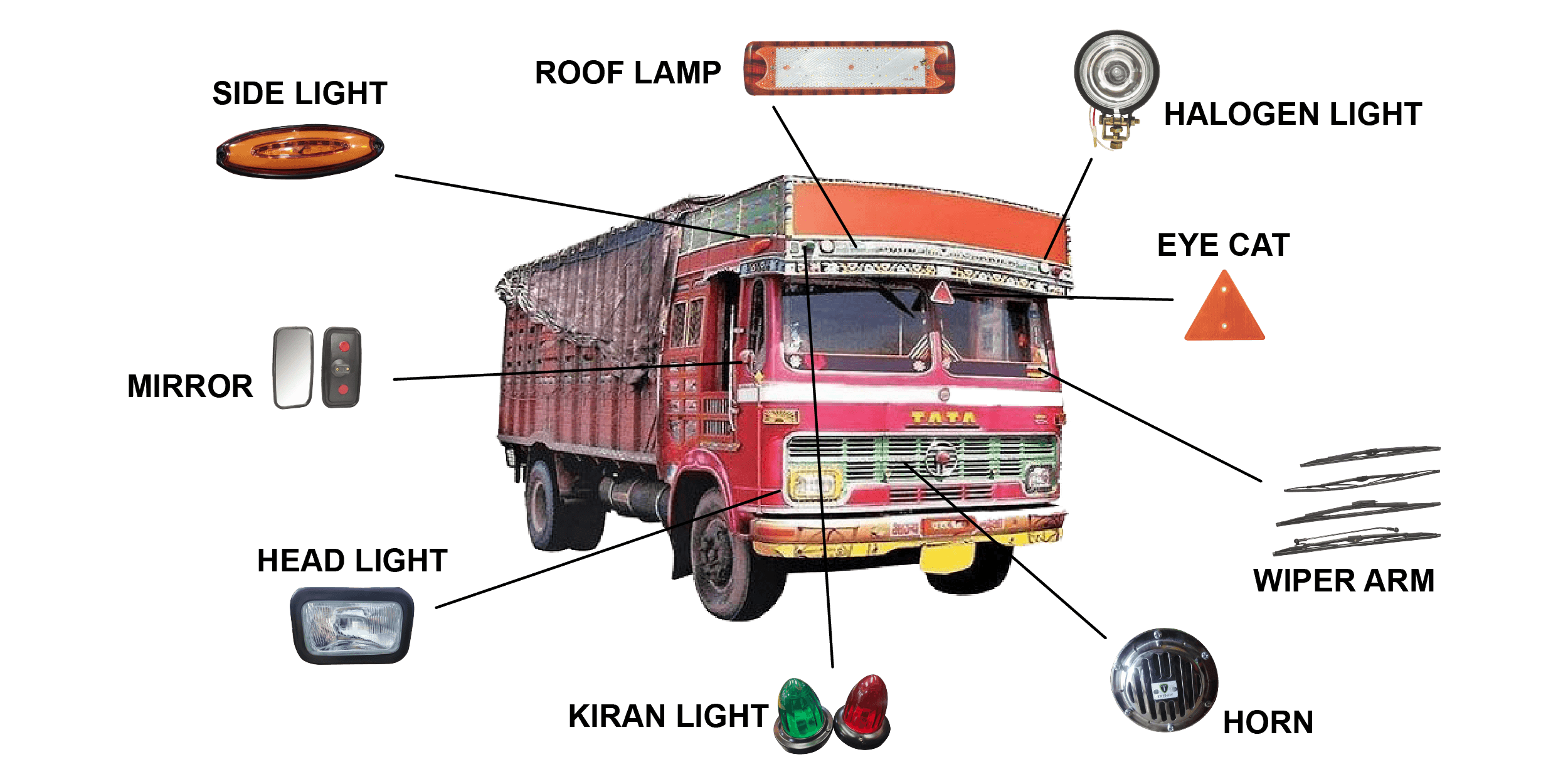

V. Essential Accessories: Lights, Markers, and Safety Features

Beyond the basic structure, several accessories are crucial for safety and visibility:

- Marker Lights: Small lights located along the sides and rear of the body, indicating the vehicle's width and length.

- Reflectors: Reflective surfaces that enhance visibility in low-light conditions.

- Side Guards/Underrun Protection: Barriers along the sides of the lorry to prevent cyclists and pedestrians from being dragged underneath.

- Reversing Camera: Provides a view of the area behind the lorry, aiding in maneuvering and preventing accidents.

VI. Price Table for Common Lorry Body Parts (Estimates Only, Prices Vary Widely)

| Part Name | Description | Estimated Price Range (USD) | Considerations |

|---|---|---|---|

| Side Panel (Steel) | Standard steel side panel for a dry van body. | $500 - $1500 per panel | Gauge of steel, dimensions, complexity. |

| Rear Door (Barn Door) | Set of two hinged barn doors for the rear of the body. | $800 - $2000 per set | Material, size, locking mechanism. |

| Tail Lift (Hydraulic) | Hydraulic tail lift for loading heavy items. | $3000 - $10,000 | Lifting capacity, platform size, brand. |

| Roller Shutter Door | Rolling door for easy access to the cargo area. | $1500 - $4000 | Material, size, activation method. |

| Load Restraint Bar | Adjustable bar to prevent cargo shifting. | $50 - $200 per bar | Length, material, locking mechanism. |

| Refrigeration Unit (Small) | Small refrigeration unit for a van body. | $2500 - $8000 | Cooling capacity, type of refrigerant. |

| Subframe (Steel) | Steel subframe for mounting the body to the chassis. | $1000 - $5000 | Length, material, complexity. |

| Marker Light (LED) | LED marker light for visibility. | $10 - $50 per light | Brightness, durability, compliance. |

| Side Guard (Aluminum) | Aluminum side guard for underrun protection. | $200 - $800 per side | Length, material, compliance. |

| Curtainsider Curtain (Each) | Replacement curtain for a curtainsider body. | $300 - $1000 per curtain | Material, size, color. |

Disclaimer: These prices are estimates only and can vary widely depending on the specific supplier, quality of materials, and installation costs. Always obtain quotes from reputable suppliers.

VII. Common Challenges and Solutions

- Corrosion: Rust is a major enemy of lorry bodies, especially in areas with harsh weather conditions. Solution: Regular cleaning, painting, and application of rust inhibitors.

- Impact Damage: Dents and cracks can weaken the body structure. Solution: Prompt repairs by qualified professionals.

- Wear and Tear: Constant use can lead to wear and tear on moving parts like doors and latches. Solution: Regular lubrication and replacement of worn parts.

- Load Shifting: Improperly secured loads can cause damage to the body and pose a safety risk. Solution: Proper load securing techniques and regular inspection of restraint systems.

VIII. Frequently Asked Questions (FAQ)

-

Q: What's the difference between a box van and a flatbed lorry?

- A: A box van has an enclosed cargo area, while a flatbed lorry has a flat, open deck.

-

Q: What materials are commonly used for lorry body construction?

- A: Steel, aluminum, fiberglass, and composite materials are commonly used, each offering different advantages in terms of strength, weight, and cost.

-

Q: How often should I inspect my lorry body?

- A: Regular inspections should be conducted at least monthly, with more thorough inspections performed annually.

-

Q: What are the legal requirements for lorry body dimensions?

- A: Legal requirements vary by country and region. Consult with local authorities for specific regulations.

-

Q: Can I customize my lorry body?

- A: Yes, lorry bodies can be customized to meet specific needs, such as adding extra tie-down points, installing specialized equipment, or modifying the dimensions.

Conclusion: Appreciating the Complexity

The lorry body is far more than just a box on wheels. It's a carefully engineered structure designed to withstand the rigors of daily use and ensure the safe and efficient transport of goods. By understanding the "Parts Of A Lorry Body By Name" and their functions, we can better appreciate the complexity of this vital piece of machinery and ensure its continued performance for years to come. This knowledge also allows for more informed maintenance, repair, and purchasing decisions, ultimately contributing to a safer and more efficient transport industry. The next time you see a lorry on the road, remember the intricate network of components working together to keep our world connected and supplied.