The truck body is more than just a shell; it's the workhorse component that determines a truck's functionality, efficiency, and even its lifespan. Understanding the different parts of a truck body is crucial for anyone involved in the trucking industry, from fleet managers to mechanics, drivers, and even those considering purchasing a truck. This comprehensive guide will break down the various components that comprise a truck body, highlighting their functions, benefits, and essential considerations for maintenance and repair.

Introduction: The Indispensable Truck Body

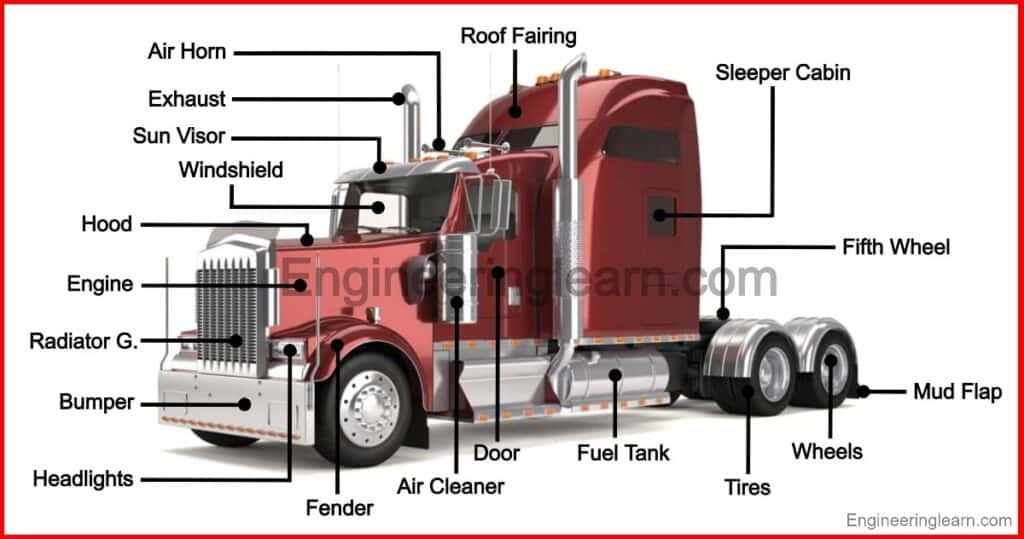

Parts Of A Truck Body: A Comprehensive Guide

The truck body, in its simplest definition, is the specialized structure mounted onto a truck chassis to carry cargo, equipment, or passengers. Its design and construction are dictated by the truck's intended purpose, ranging from hauling construction materials to transporting refrigerated goods across the country. The integrity and functionality of the truck body are paramount to the success of any trucking operation. A well-maintained and appropriately equipped truck body ensures safe and efficient transport, minimizes downtime, and maximizes the return on investment. Neglecting the body can lead to cargo damage, increased fuel consumption, safety hazards, and costly repairs. This guide will equip you with the knowledge to understand, maintain, and appreciate the complex engineering behind this essential component.

1. Cab: The Control Center

The cab is the compartment where the driver operates the truck. It's the most recognizable part of the truck body and houses all the necessary controls and instruments.

-

Key Components:

- Chassis Mounts: These secure the cab to the truck's frame, absorbing vibrations and shocks.

- Doors: Providing access to the cab, doors are crucial for driver entry and exit. Quality hinges, latches, and seals are essential for weather protection and security.

- Windows: Offering visibility and ventilation, windows need to be durable and resistant to cracking or shattering.

- Windshield: The primary window, providing a clear view of the road. It's often made of laminated safety glass for enhanced protection.

- Roof: Protecting the driver from the elements, the roof can also house air conditioning units, antennas, and other accessories.

- Floor: The base of the cab, often covered with durable flooring material for wear resistance.

- Dashboard: Containing essential gauges, controls, and displays, the dashboard provides vital information to the driver.

- Seats: Designed for comfort and support, truck seats are often adjustable and equipped with suspension systems to mitigate vibrations.

- Steering Wheel: The primary control for directing the truck.

- Pedals: Controlling acceleration, braking, and clutch (if applicable).

-

Benefits: A well-designed and maintained cab contributes to driver comfort, safety, and efficiency. Ergonomic features and clear visibility reduce fatigue and improve reaction times.

-

Important Considerations: Regular inspection and maintenance of cab components are crucial. Damaged seals can lead to water leaks, and worn-out suspension can reduce ride comfort.

2. Cargo Area: The Heart of the Operation

The cargo area is the section designed to hold and transport goods. Its specific design varies widely depending on the truck's purpose.

-

Types of Cargo Areas:

- Flatbeds: A basic platform for carrying oversized or irregularly shaped items.

- Box Trucks: Enclosed cargo areas offering protection from the elements and increased security.

- Refrigerated Trucks (Reefers): Insulated cargo areas with temperature control systems for transporting perishable goods.

- Tankers: Designed for transporting liquids or gases.

- Dump Trucks: Equipped with a hydraulic lift to dump loads of materials like gravel or sand.

-

Key Components (Generic):

- Flooring: Providing a stable surface for cargo, flooring must be durable and resistant to wear and tear.

- Walls: Enclosing the cargo area and protecting the contents.

- Roof: Protecting the cargo from the elements.

- Doors/Gates: Providing access to the cargo area for loading and unloading.

- Tie-Down Points: Securely fastening cargo to prevent shifting during transit.

-

Benefits: A properly designed and maintained cargo area ensures the safe and efficient transport of goods, minimizing damage and loss.

-

Important Considerations: Regular inspection for damage, such as cracks, dents, and corrosion, is essential. Ensure tie-down points are in good condition and capable of handling the intended load. For refrigerated trucks, proper insulation and refrigeration system maintenance are critical.

3. Exterior Body Panels: Protection and Aesthetics

These panels form the outer skin of the truck body, providing protection from the elements and contributing to the truck's overall appearance.

-

Key Components:

- Hood: Covering the engine compartment, the hood provides access for maintenance and repairs.

- Fenders: Protecting the wheels and preventing debris from being thrown onto the truck or other vehicles.

- Side Panels: Covering the sides of the truck body, providing protection and aerodynamic efficiency.

- Rear Panels: Enclosing the rear of the truck body.

- Bumpers: Providing impact protection in the event of a collision.

-

Materials: Commonly made from steel, aluminum, fiberglass, or composite materials, each offering different advantages in terms of weight, durability, and corrosion resistance.

-

Benefits: Exterior panels protect internal components from damage and contribute to the truck's overall structural integrity.

-

Important Considerations: Regular cleaning and waxing can help protect the paint and prevent corrosion. Damage to panels should be repaired promptly to prevent further deterioration.

4. Lighting and Electrical Systems: Visibility and Functionality

The lighting and electrical systems are crucial for safety, visibility, and the operation of various truck body components.

-

Key Components:

- Headlights: Providing illumination for driving at night or in low-visibility conditions.

- Taillights: Signaling the truck's presence to other drivers.

- Brake Lights: Indicating when the brakes are applied.

- Turn Signals: Signaling the driver's intention to turn or change lanes.

- Marker Lights: Indicating the truck's size and shape.

- Work Lights: Providing illumination for loading and unloading cargo.

- Wiring Harness: Connecting all electrical components.

- Batteries: Providing power to the electrical system.

-

Benefits: Proper lighting ensures safe driving conditions, while a reliable electrical system powers essential components.

-

Important Considerations: Regularly inspect all lights to ensure they are functioning correctly. Check wiring for damage and corrosion. Ensure batteries are properly charged and maintained.

5. Underbody Components: Structural Support and Protection

These components provide structural support and protection for the truck body.

-

Key Components:

- Frame: The backbone of the truck, providing structural support for all other components.

- Crossmembers: Reinforcing the frame and preventing twisting.

- Suspension System: Absorbing shocks and vibrations, providing a smooth ride.

- Axles: Supporting the wheels and transmitting power from the engine.

- Wheels and Tires: Providing traction and allowing the truck to move.

-

Benefits: A strong and well-maintained underbody ensures the truck's stability, handling, and safety.

-

Important Considerations: Regular inspection for damage, corrosion, and wear is essential. Proper lubrication of suspension components is crucial for smooth operation.

Practical Advice and Actionable Insights:

- Regular Inspections: Implement a routine inspection schedule to identify potential problems early.

- Prompt Repairs: Address any damage or wear immediately to prevent further deterioration.

- Proper Maintenance: Follow the manufacturer's recommendations for maintenance and lubrication.

- Professional Assistance: Don't hesitate to seek professional assistance for complex repairs or maintenance.

- Consider Upgrades: Evaluate opportunities to upgrade components for improved performance, efficiency, or safety.

Price Table of Truck Body Parts

| Part | Description | Estimated Price Range (USD) | Notes |

|---|---|---|---|

| Cab Assembly | Complete cab structure (excluding interior) | $5,000 - $20,000 | Varies significantly based on model, year, and condition. |

| Flatbed (24 ft) | Complete flatbed platform | $3,000 - $8,000 | Price depends on material (steel, aluminum), thickness, and features. |

| Box Truck Body (20 ft) | Enclosed cargo area (excluding refrigeration) | $8,000 - $20,000 | Price varies based on material, insulation, and door types. |

| Reefer Unit (Truck) | Refrigeration unit for refrigerated trucks | $5,000 - $15,000 | Price depends on cooling capacity, features, and brand. |

| Dump Truck Body (10-14ft) | Hydraulic lift dump bed | $10,000 - $30,000 | Price depends on capacity, material, and hydraulic system. |

| Truck Door (Single) | Replacement door (excluding hardware) | $500 - $2,000 | Price depends on model, material, and complexity. |

| Windshield | Laminated safety glass windshield | $300 - $1,000 | Price depends on size, features (heated, rain sensor), and brand. |

| Bumper (Front/Rear) | Steel or aluminum bumper | $200 - $1,000 | Price depends on material, size, and features. |

| Headlight Assembly | Complete headlight unit (excluding bulb) | $100 - $500 | Price depends on type (halogen, LED), and brand. |

| Taillight Assembly | Complete taillight unit (excluding bulb) | $50 - $300 | Price depends on type (LED), and brand. |

| Tie-Down Strap (Heavy Duty) | Cargo securing strap | $20 - $50 | Price per strap; quantity needed depends on cargo. |

| Mud Flaps (Pair) | Wheel spray guards | $30 - $100 | Price depends on size and material. |

Note: These are estimated price ranges and can vary significantly based on location, supplier, and specific truck model. Labor costs for installation are not included. Always get a quote from a reputable supplier or mechanic.

Conclusion: Investing in the Longevity of Your Truck Body

The truck body is a critical investment that requires careful attention and maintenance. Understanding its various components, their functions, and potential issues is essential for maximizing its lifespan and ensuring safe and efficient operation. By implementing a proactive maintenance program and addressing problems promptly, you can protect your investment and keep your trucks on the road for years to come. Remember, a well-maintained truck body is not just about aesthetics; it's about safety, efficiency, and profitability.

Frequently Asked Questions (FAQ)

Q: How often should I inspect my truck body?

A: Ideally, a visual inspection should be performed before each trip. A more thorough inspection, including checking for rust, corrosion, and damage, should be conducted at least monthly.

Q: What are the signs of a failing truck body?

A: Common signs include rust, corrosion, cracks, dents, leaks, loose panels, and malfunctioning lights.

Q: Can I repair a truck body myself?

A: Minor repairs, such as replacing lights or tightening bolts, can often be done yourself. However, more complex repairs, such as welding or body panel replacement, should be performed by a qualified technician.

Q: What is the best way to prevent rust on my truck body?

A: Regular cleaning and waxing, applying rust inhibitors, and addressing any scratches or chips in the paint promptly can help prevent rust.

Q: How can I improve the fuel efficiency of my truck body?

A: Consider using aerodynamic accessories, such as fairings and side skirts, to reduce drag. Also, ensure the cargo is properly secured to prevent shifting and improve stability.

Q: What type of truck body is best for my needs?

A: The best type of truck body depends on the specific application. Consider the type of cargo you will be hauling, the environmental conditions, and any special requirements, such as temperature control. Consulting with a truck body specialist can help you make the right choice.